As discussed in the previous article, currently there are 2 classifications of plastics, namely rigid and flexible. But, have we ever asked how rigid plastic products are produced? This article will discuss in general the production process from raw materials plastic to plastic products.

Until now, plastic production technologies have developed in the world. Medion Plastic as a plastic manufacturer with more than 25 years of experience has modern technology to produce plastic products to be marketed both in Indonesia and overseas . The technologies we currently use include the following : Injection Molding Machine, Blow Molding Machine, Injection-Blow Molding Machine, Extrude Machine and Inject Stretch Blow Molding.

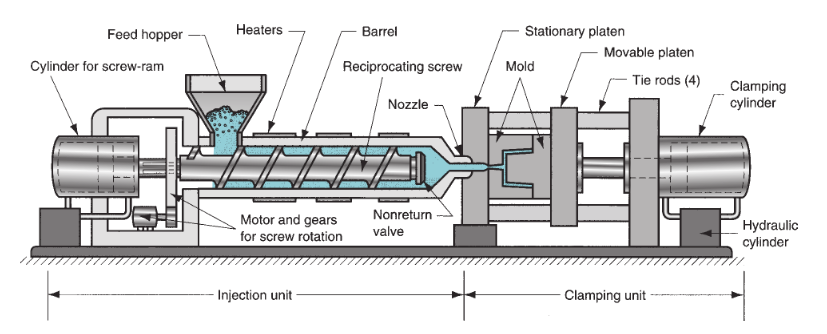

1. Injection Molding Machine

Picture 1 : Injection Molding Machine

(Source : M. P. Groover, 2010, Fundamentals of Modern Manufacturing: Materials, Processes, and Systems, edition 4)

First, in the injection molding machine process, raw material plastic will later be put into a tube that has a heater. After the plastic material is melted, then will be injected into the mold which becomes a product. This injection molding process is usually used to produce products with a high accuracy such as bottle caps, plastic parts, etc.

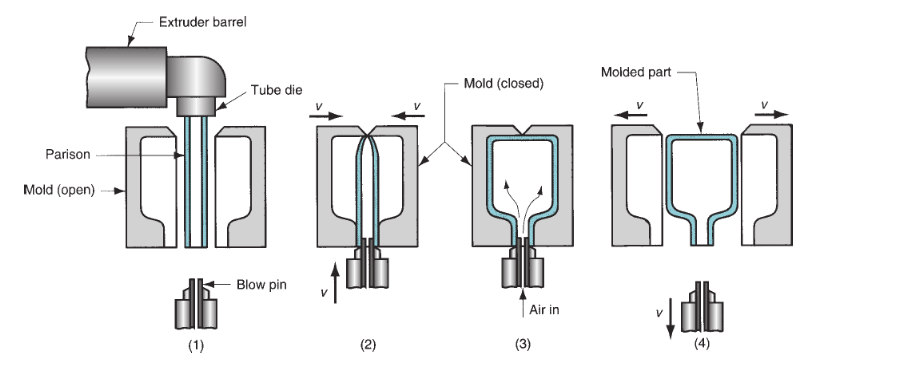

2. Blow Molding Machine

Picture 2 : Blow Molding Machine

(Source : M. P. Groover, 2010, Fundamentals of Modern Manufacturing: Materials, Processes, and Systems, edition 4)

In the blow molding process, the melted plastic initially will be formed into a porison. Then this porison will be clamped by the mold and air will be blown through by the blow pin to form a product that fits the mold. This blow molding process is usually used to produce plastic products that have a cavity or volume such as medicine packaging bottles, Med Spray bottles, Medion chicken drinker and many others.

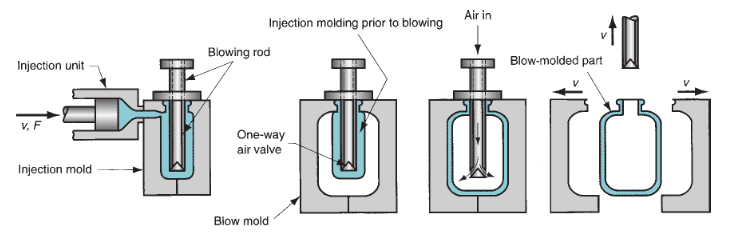

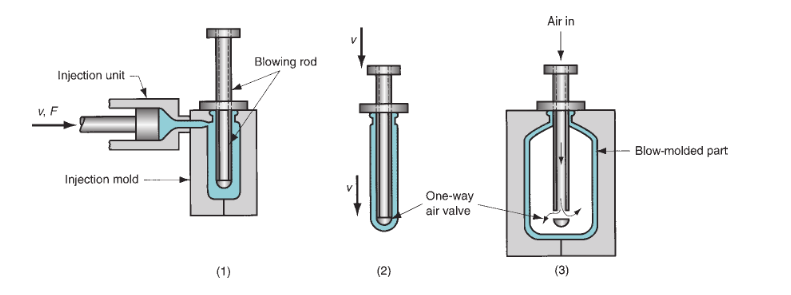

3. Injection Blow Molding Machine

Picture 3 : Injection Blow Molding Machine

(Source : M. P. Groover, 2010, Fundamentals of Modern Manufacturing: Materials, Processes, and Systems, edition 4)

The Injection-blow molding process is a combination of the injection and blow processes. In the first process, the plastic material will be melted to form a preform by the injection process. And then, the preform will go into the blow mold to form the body of product by blowing it. This process is usually used for products that require high precision and consistency in the product.

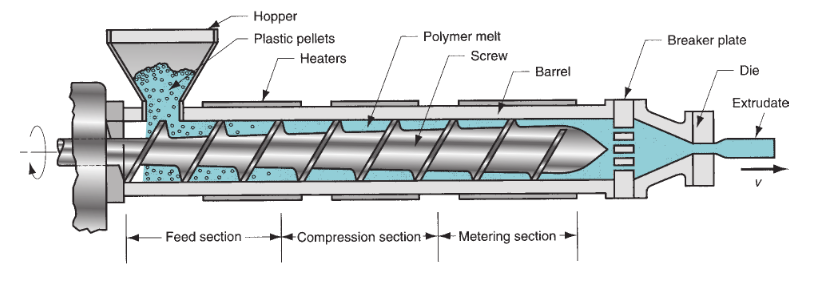

4. Extrude Machine

Picture 4 : Extrude Machine

(Source : M. P. Groover, 2010, Fundamentals of Modern Manufacturing: Materials, Processes, and Systems, edition 4)

In the extrude process, the plastic material is melted which is then continuously pressed through the die holes to produce a long continuous product whose cross-sectional shape is determined by the shape of the hole. Extrude process is usually used to produce products that have long and hollow dimensions such as hoses, pipes etc.

5. Injection Stretch Blow Molding Machine

Picture 5 : Injection Stretch Blow Molding

(Source : M. P. Groover, 2010, Fundamentals of Modern Manufacturing: Materials, Processes, and Systems, edition 4)

This Injection Stretch Blow Molding machine is generally used to produce PET (polyethylene terephthalate). In principle, the mechanism of this machine is almost the same as Injection-blow molding. At the initial stage, the raw material of plastics melted and formed into a preform. Then, the preform is stretched according to the desired dimensions. After that, the air is blown to form the product according to the mold.

Hopefully this article can help all readers to get a better idea of the production process and the technology used in the production of rigid plastics. Medion Plastic, always continue to innovate technology in order to provide what customers need and can provide the best service to our customer.