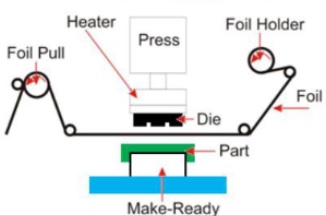

Hot stamping is a printing method used to add logos, color accents, or specific information to plastic packaging by using heat and pressure to stick foil ink to the printed plastic packaging. This process is carried out using a film or foil, which is a thin sheet of plastic composed of several layers. The heat from the mold will activates certain layers of the film/foil, causing it to stick to the processed plastic/product.

- Durability and Longevity

Hot stamping produces decorations with relatively better durability compared to other methods. The colors, designs, or logos applied through hot stamping do not easily peel off, fade, or get damaged by heat or even chemicals, ensuring the product looks good for a long time. - More Aesthetic Plastic Packaging Appearance

This method can use various types of foil that provide high-quality finishes, such as metallic, holographic, or specific textures. This enhances the visual appeal of the product, making it more attractive to consumers. - Safety and Clarity of Information

Important information such as logos, usage instructions, or product details processed through hot stamping is relatively clearer and more durable. This helps in the accurate delivery of information and ensures that consumers can easily identify and use the product correctly. - Environmentally Friendly

Since hot stamping is a dry processing method, it does not involve the use of harmful chemicals or solvents that could pollute the environment.

Hot stamping can be an attractive alternative for companies that looking to enhance the quality and appeal of their products. Medion Plastic is committed to always providing the best solutions to produce high-quality products that meet customer needs.

Hot Stamping on Plastic Packaging