Injection Stretch Blow Molding (ISBM) is a cutting-edge technology utilized in the production of high-quality hollow plastic containers, such as bottles, jars, and pharmaceutical packaging. This technology integrates both injection molding and blow molding processes, resulting in enhanced efficiency, improved product properties, and reduced production costs. ISBM is primarily employed in the manufacturing of PET, PP, or PC bottles, which are widely used in beverage packaging, personal care products, and pharmaceuticals.

Injection Stretch Blow Molding Process

The Injection Stretch Blow Molding (ISBM) process is typically categorized into two distinct methods: the single-stage process and the two-stage process.

- Single-Stage Process:

In the single-stage method, both the production and forming of the preform (the initial bottle shape) occur within a single, integrated machine. This method typically involves three or four distinct stages: injection molding, reheating (if required), stretching and blowing, and ejection of the final product. A notable advantage of this approach is the significant reduction in capital investment for machinery, along with energy efficiencies. Since the preform does not need to be fully cooled before the blow molding stage, this method optimizes energy consumption and reduces cycle time, making it cost-effective for high-volume production.

- Two-Stage Process:

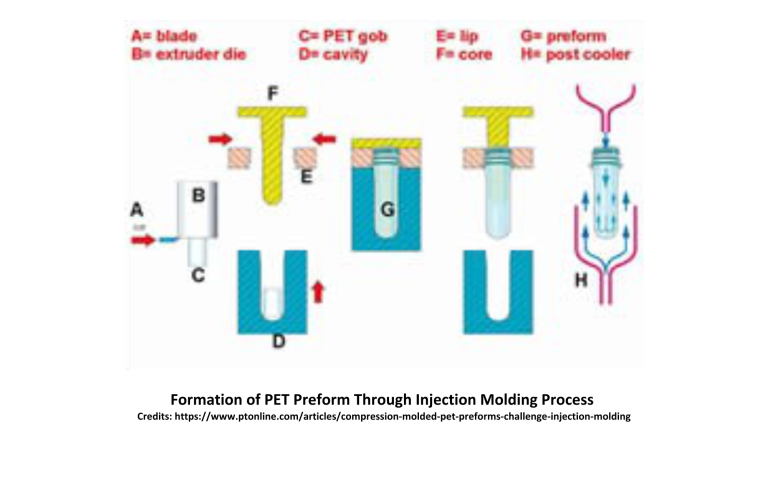

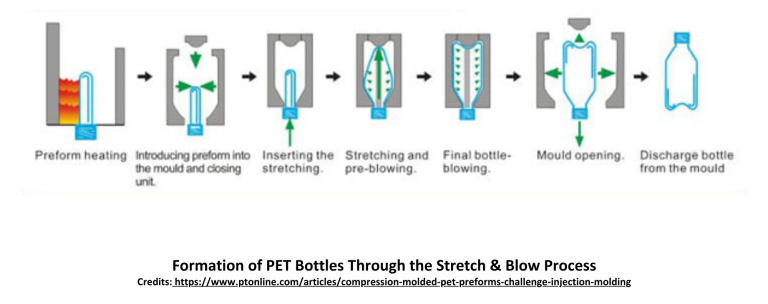

In the two-stage method, the preform is first manufactured through injection molding. It is then reheated to an optimal temperature to ensure it is malleable enough for the blow molding process. Subsequently, the preform is placed in a blow mold and inflated using high-pressure air to achieve the desired shape of the container. This method provides greater flexibility in terms of production volumes and allows for more control over the final product’s quality, particularly in complex or highly precise applications. The two-stage process is often preferred for larger-scale production and when uniformity in wall thickness and structural integrity are critical.

Advantages of ISBM Technology

ISBM technology offers several notable advantages over alternative methods, including:

- Superior Product Quality

The biaxial (two-directional) stretching process during the blow molding phase significantly enhances the mechanical strength, impact resistance, and optical clarity of the final product. This makes ISBM particularly suited for applications in pharmaceutical packaging, carbonated beverage containers, and other high-performance packaging solutions that demand exceptional product integrity and clarity.

- Design Versatility and Precision

ISBM provides unparalleled flexibility in producing a diverse range of bottle shapes and sizes, all while maintaining uniform wall thickness. This level of control allows for advanced packaging design possibilities, enabling the creation of complex and aesthetically appealing container shapes without compromising structural performance.

- Enhanced Production Efficiency

By seamlessly integrating both injection molding and blow molding stages, ISBM significantly reduces production cycle times, minimizes labor costs, and enhances overall operational efficiency. This streamlined process not only optimizes resource utilization but also results in reduced energy consumption and improved cost-effectiveness, making it an ideal choice for high-volume manufacturing environments.

Application of ISBM Technology at Medion Plastic

In its production process, Medion Plastic has long utilized ISBM technology to manufacture high-quality plastic containers. Some of the premium products produced using this technology include 60ml PET Bottle, 100ml PET Bottle, and Pro Round Bottle. These products showcase the efficiency and precision that ISBM technology offers, ensuring durability, consistency, and optimal performance for a wide range of packaging needs.